[ad_1]

The American Composites Manufacturing Association, ACMA, proclaimed the HSM the winner of the ACE Award for Unsurpassed Innovation in the ‘Manufacturing: Equipment and Tooling’ category. This award is presented annually to equipment, tooling, a production aid, or software designed to improve manufacturing production, environmental sustainability, or product quality and performance in composites manufacturing, the company said in a press release.

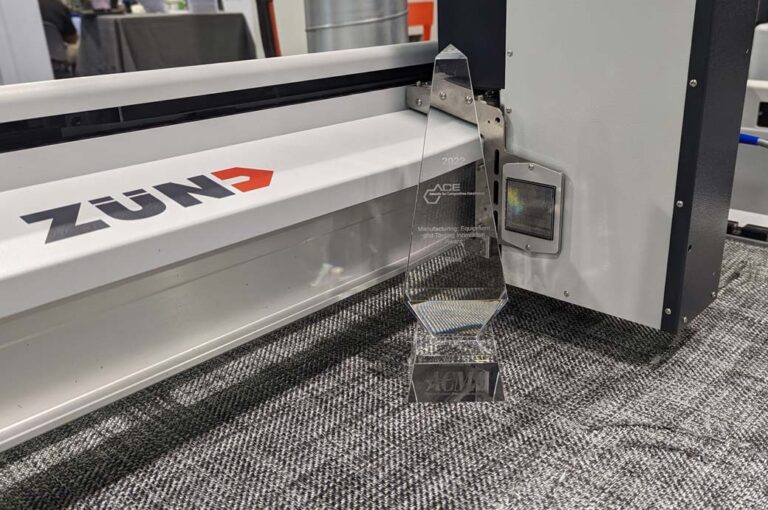

The Heat Sealing Module (HSM) from Zund has bagged the Unsurpassed Innovation award at the recently held CAMX 2022 Composites and Advances Materials expo in Anaheim, California. The HSM facilitates the processing and handling of dry fibre materials with thermoplastic content. This new tool helps in the easier processing of these types of materials.

During processing, dry fibre materials are prone to fraying along the edges. Using hot air, the HSM seals the fabric along the cut path in advance of the Zünd Power Rotary Tool – PRT cutting it. Because of this sealing process, the cut can then be performed at full speed, in any direction, and produces both higher-quality parts and greater production efficiencies.

The HSM helps create clean, sealed edges when cutting fibre-reinforced thermoplastic composites. It benefits not only the cutting process itself, but other production processes downstream. Cutting this way leaves behind no loose or uncut fibres and maintains a clean cutting surface and uncontaminated production environment. At the same time, it ensures that cut parts maintain their shape, and this increased stability makes them much easier to handle, especially in fully automated production workflows.

Fibre2Fashion News Desk (GK)

[ad_2]

Source link