[ad_1]

Refashion is actively working to promote textile and footwear recycling and focusing on the industrial potential of open loop recycling, which involves recovering used household textiles for use in sectors beyond the textile industry, the eco-organisation said in a report.

Refashion has developed a high-performance insulating nonwoven made from post-consumer clothing for the transport sector through its Transport Nonwovens WG. The WG has identified four key stages, including identifying feedstock sources, pre-feasibility tests, characterising resulting products, and technical-economic assessment, to develop the nonwoven.

Toni Gallone, ex technical director at Renault and CEO of ICRM (Impulse Circula’r Raw Materials), is heading the WG. Gallone’s role in the group is to define the manufacturing process, the industrial scheme, and business model. The WG’s working areas include a layer of randomly or directionally aligned fibres, bound by friction and/or cohesion and/or adhesion, which are notably used as acoustic absorbers in the transport sector.

Some manufacturers, including Volvo, Renault, and PSA, have already committed to using more recycled materials in newly designed vehicles. The nonwoven made from post-consumer clothing will meet the expected features of products manufactured with these materials. However, the development of these eco-designed products has been hampered by higher costs and potential risks linked with using recycled materials. The Nonwovens WG has been particularly vigilant on these two latter points.

The WG has identified and implemented four key stages, including the identification of feedstock sources, stakeholders, and transformation processes, pre-feasibility tests, characterisation of resulting products, reproducing tests, development of a prototype and validation plan of the eco-designed product, and technical-economic assessment and evaluation of the industrial scheme.

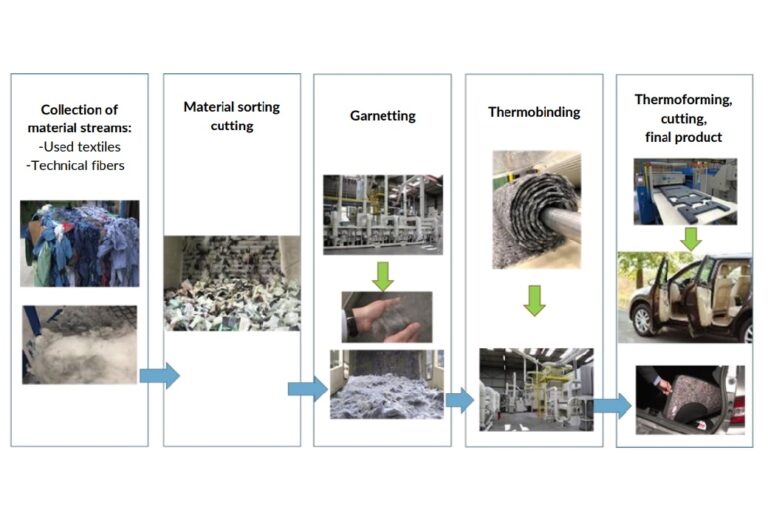

To study the project’s feasibility, a range of nonwoven samples was developed at the CETI (European Innovative Textiles Centre). The manufacturing process involved used non-reusable clothing and household linen being collected, sorted per fibre type, then cut up into rags before garnetting. Once garnetted, fibres are thermobound, i.e., heated with hot melt additives, in this case, thermobinding fibres. The nonwoven material is thereby obtained and transformed into a finished product: cuttings, addition of covering layers, and finalisation of the thermoforming process.

Ten samples were made from used non-reusable textiles, with the addition of technical fibres (rPET and PA) and BiCo thermobinding fibres. Samples varied in terms of thickness, surface mass, and fibre proportions.

Nonwovens made from used non-reusable textiles must meet certain properties to be introduced into the transport market. These properties include acoustic performance, being lightweight, having recycled and recyclable content, heat resistance, and combustibility. The technical challenge is to find the compromise between the right quantity of raw materials used for the product and its acoustic properties, knowing that it is possible to play with the ratios of the three fibre types (recycled, technical, and thermobinding fibres) in the mix when manufacturing the nonwoven samples.

Fibre2Fashion News Desk (KD)

[ad_2]

Source link