[ad_1]

Santex’ goal is to maximise performance with low energy consumption to achieve low residual shrinkage, smoother handle and silk-like appearance. The lines are equipped with various energy saving options, benefiting customers through sustainable production and low CO2 levels, the company said in a press release.

Santex Rimar, a leader in technology for textile finishing of high-quality knitted fabrics, will show its innovative solutions for high productivity and sustainable production at ITMA. The company aims to maximise performance with low energy consumption, achieving low residual shrinkage, smoother handle, and silk-like appearance in their finished products.

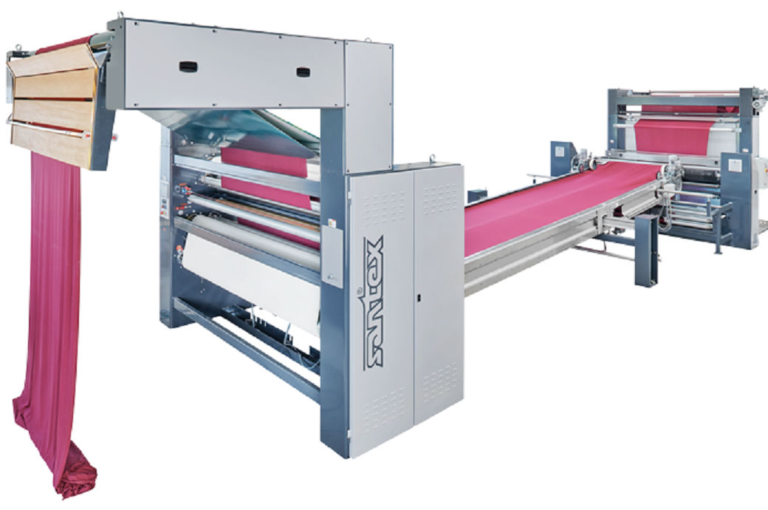

With Santaframe and Santacompact RDA, Santex Rimar will present its well-known stenter frame in combination with the felt belt compacting machine for the finishing of high-quality open-width knitted fabrics as well as applicable for woven fabrics, at ITMA.

The outstanding performance and production of the Santaframe is based on continual development using the latest advances in thermodynamics, allied to the changing need of customers. The heating system is located above the fabric web in the upper part of the 2 m treatment zone. An air circulation fan draws the air from the nozzles and the treatment zone through the filter panels and guides it along a short path to the heat exchanger, from where it is fed into the nozzles.

The arrangement of the heat source on the pressure side of the air circulation fan enables a high air circulation speed and uniform heat distribution over the entire fabric width, thus achieving an unrich drying performance. This technology results in high energy savings and cost reductions in the drying and heat-setting process of textile fabrics.

Fibre2Fashion News Desk (RR)

[ad_2]

Source link