[ad_1]

The development is based on a conductive metal-organic framework developed at the college

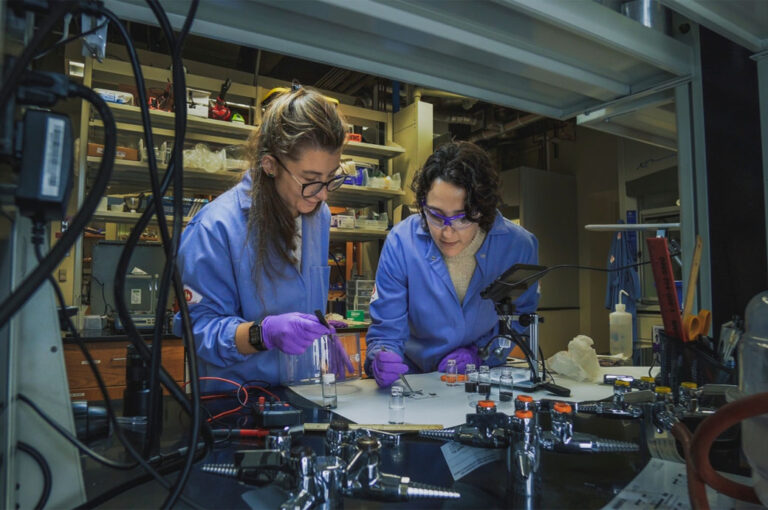

US researchers have developed a durable copper-based coating that can be precisely integrated into fabric to create responsive and reusable materials like protective equipment, environmental sensors and smart filters. The coating responds to the presence of toxic gases in the air by converting them into less toxic substances that become trapped in the fabric

Reported in the Journal of the American Chemical Society (JACS) in 2017, the framework was a simple coating that could be layered onto cotton and polyester to create smart fabrics the researchers named SOFT—self-organised framework on textiles. The paper demonstrated that SOFT smart fabrics could detect and capture toxic substances in the surrounding environment.

For the latest study, also reported in JACS, the researchers found that instead of the simple coating reported earlier, they can precisely embed the framework into fabrics using a copper precursor that allows them to create specific patterns and more effectively fill in the tiny gaps and holes between threads.

The team found that the framework technology effectively converted the toxin nitric oxide into nitrite and nitrate, and transformed the poisonous, flammable gas hydrogen sulfide into copper sulfide.

The framework’s ability to capture and convert toxic materials withstood wear and tear, as well as standard washing, an official press release said.

The versatility and durability the new method provides would allow the framework to be applied for specific uses and in more precise locations, such as a sensor on protective clothing, or as a filter in a particular environment, said corresponding author Katherine Mirica, an associate professor of chemistry at the college.

“This new method of deposition means that the electronic textiles could potentially interface with a broader range of systems because they’re so robust,” she said. “This technological advance paves the way for other applications of the framework’s combined filtration and sensing abilities that could be valuable in biomedical settings and environmental remediation.”

The technique also may prove to be a low-cost alternative to limited and expensive technologies that are cost prohibitive and limited in where they can be deployed by needing an energy source, or—such as catalytic converters in automobiles—rare metals, Mirica added.

Fibre2Fashion News Desk (DS)

[ad_2]

Source link